This tutorial is a reference manual for Camdent equipment calibration. Please operate the calibration in strict accordance with the requirements。

Prepare tools

Thickness gauge, 12mm wax blank, one set of hexagonal wrench, and lathe burs T1 (φ 2) and T2 (φ 1) ① confirm that the tool number is 0 (no tool status) after startup, and if not, it is necessary to clamp the actual clamping tool of the spindle onto the spindle to synchronize its display with the actual one. Consult the manufacturer for the operation method. It must be confirmed that the displayed tool number is the same as the actual tool before running the equipment

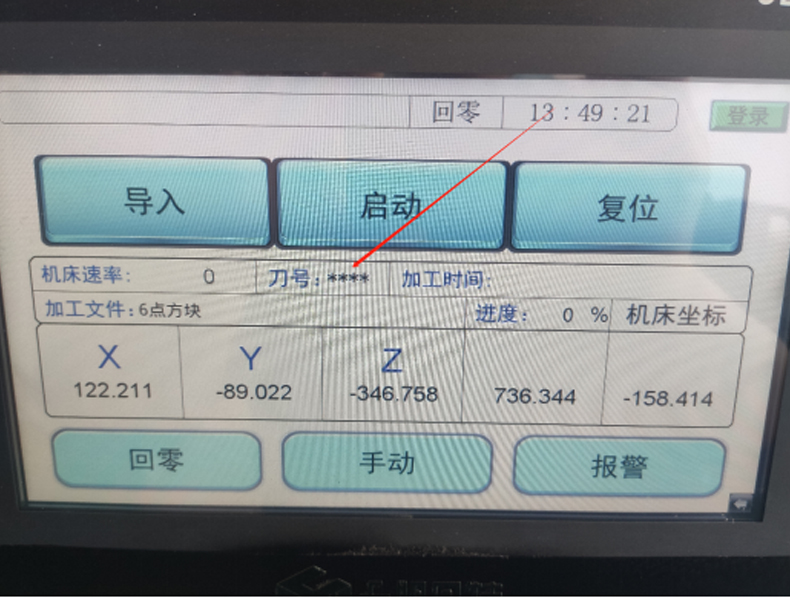

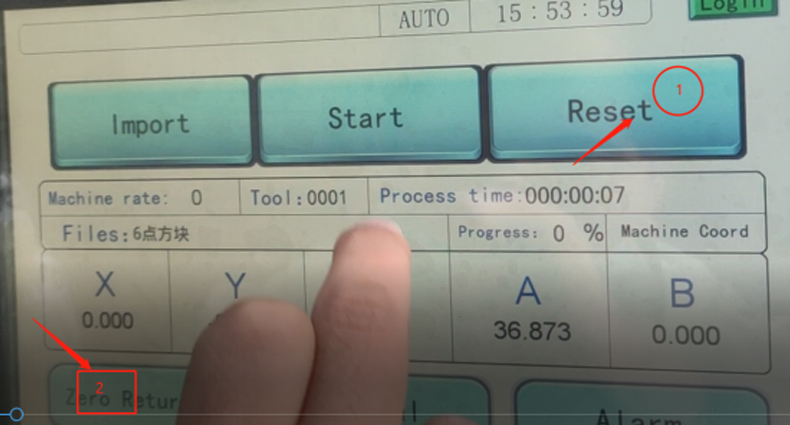

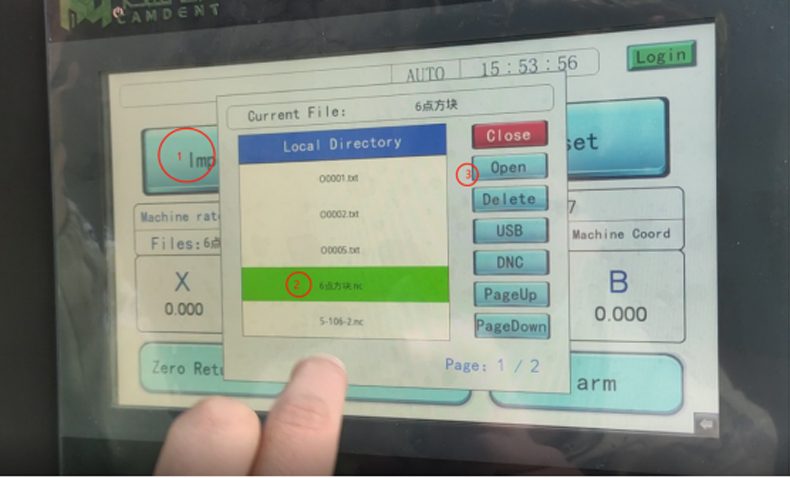

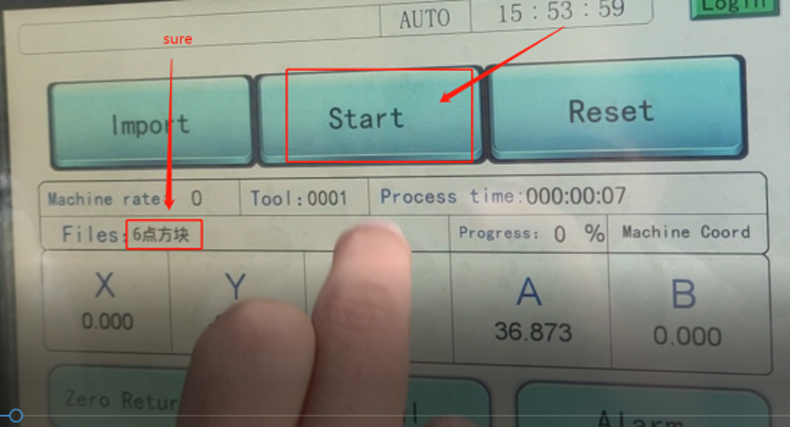

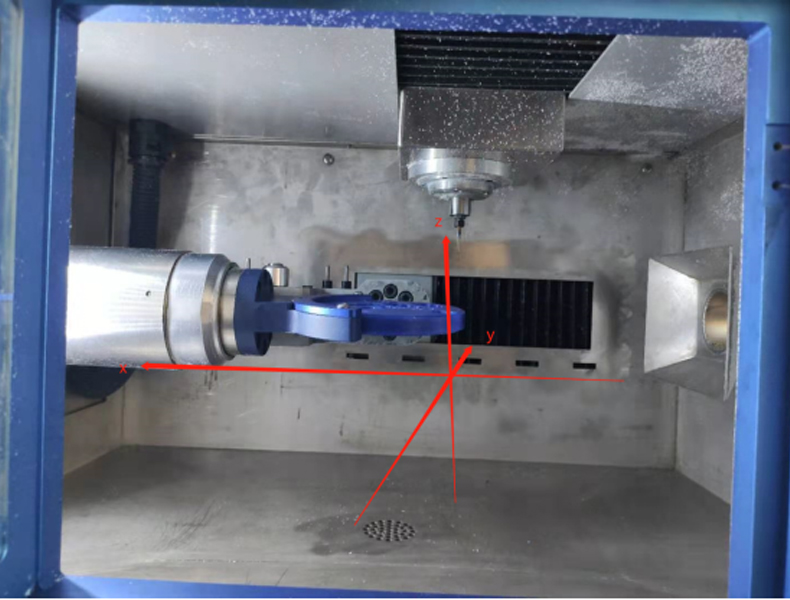

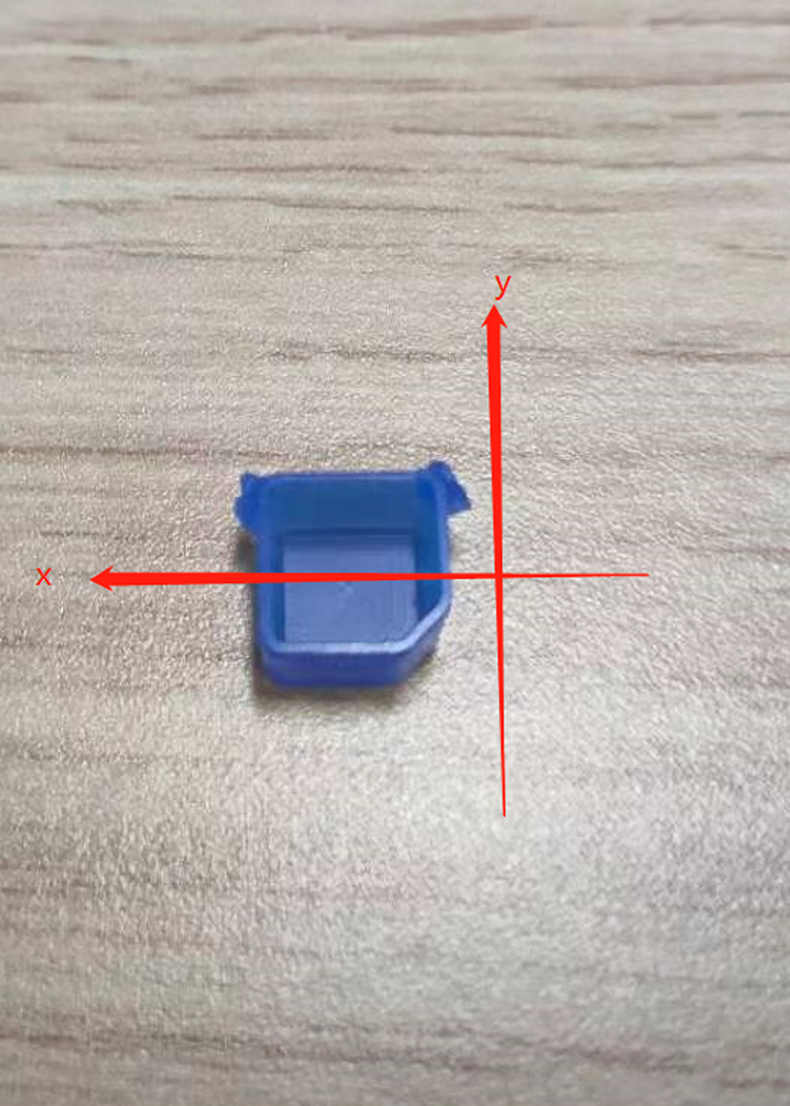

(1)The above-mentioned equipment is ready to reset after clamping the wax tray, and then return to zero, and then enter the non-operational

preparation state. Select "Six-Point Square" under the Import button to select Start

(2)

Equipment returns to zero

2.2 Import test program processing

3、Processing is complete

3.1 Confirm the Y and Z directions of the equipment. If you can't determine the direction, you can click the axial direction in the manual mode of the main page to move xyz slightly to try the direction. Note that the spindle can only be operated in a safe position, otherwise it is easy to collide and damage the equipment。

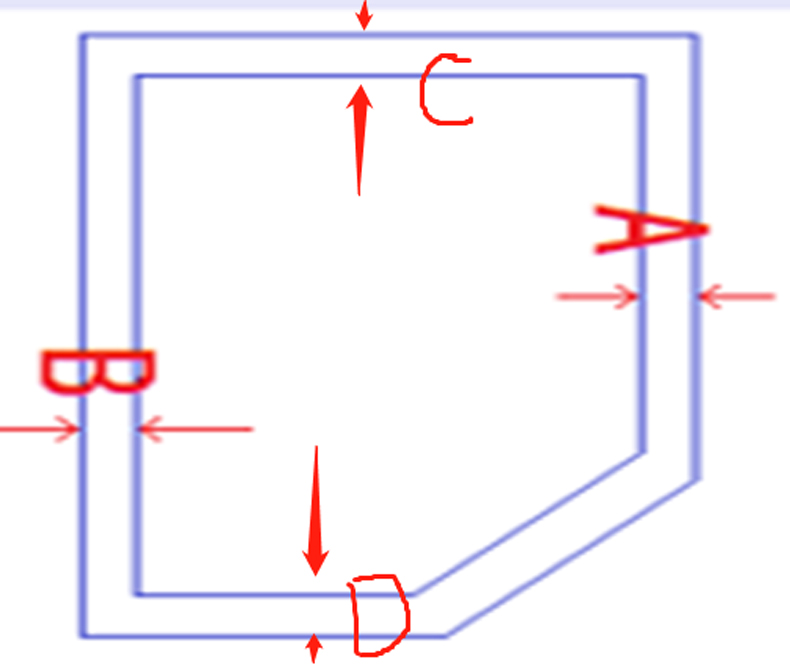

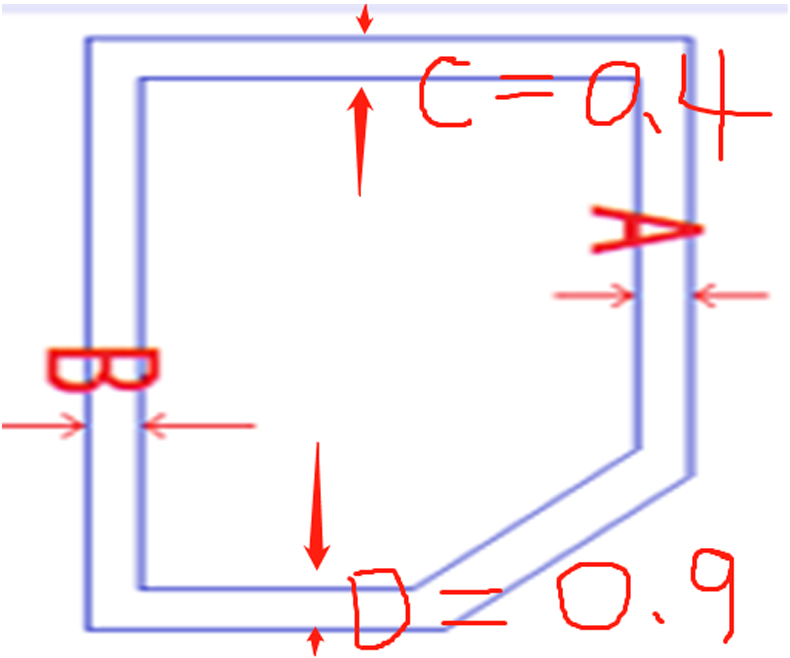

4. According to the above operation, we can know that the direction

Convert to an image as follows

A=B is on the x-axis, and table coordinates are set for the machine tool without adjustment. C and d are on the y axis, so we need to finely adjust the compensation value of the y axis. ① When C is greater than D, we need the compensation box to compensate in the positive direction of Y, and the compensation formula is (C-D)/2= positive number ② when C is less than D, we need to compensate in the negative direction of compensation box y, and the formula is (C-D)/2= negative number. ③ When C equals D, we don't need compensation. Note: Because there is an objective measurement error, the above C=D means that when the error between C and D is 0.02, we can determine the equality.

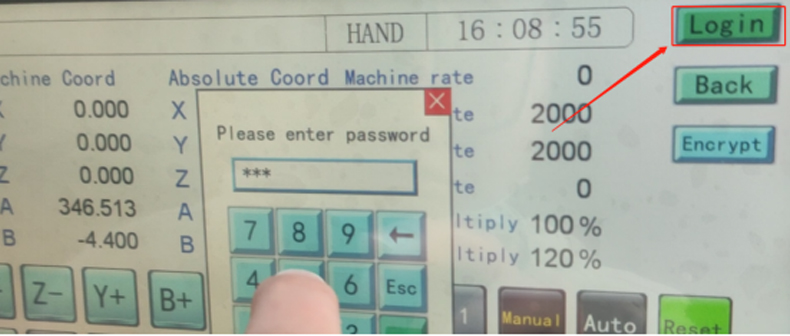

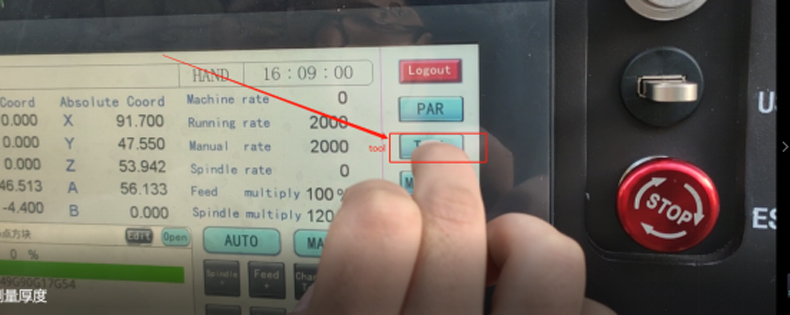

5. The compensation value is input into the base deviation window of the equipment. The following is the operation method,

①Login password

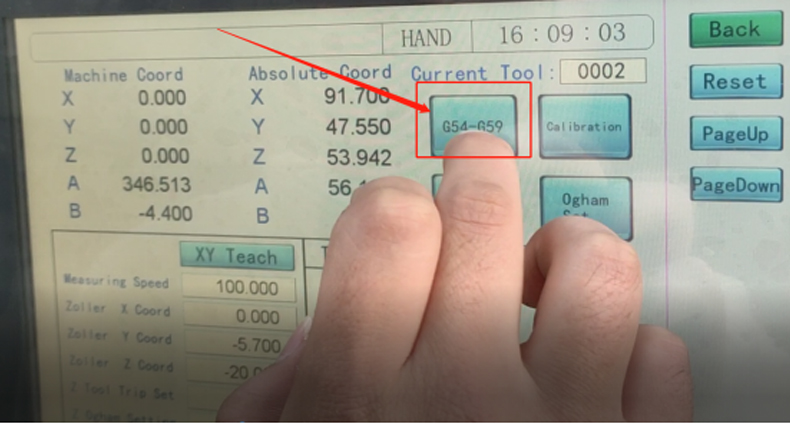

Then enter the tool page

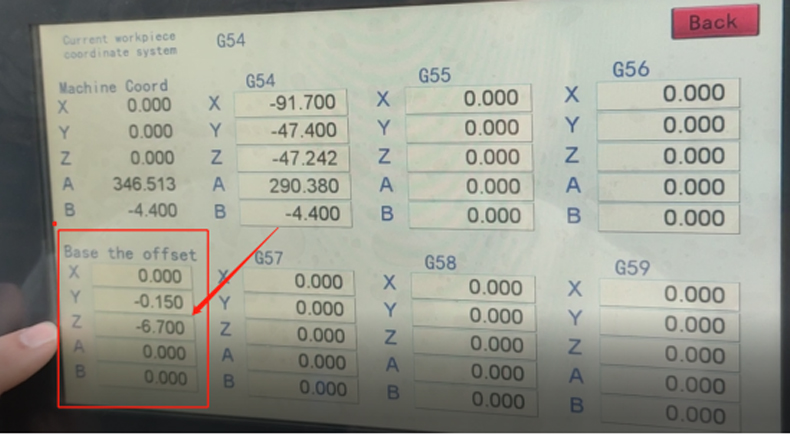

②Enter G54-G59

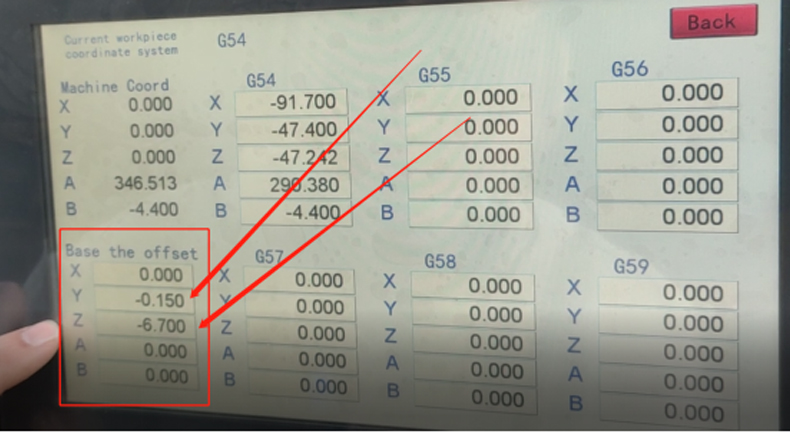

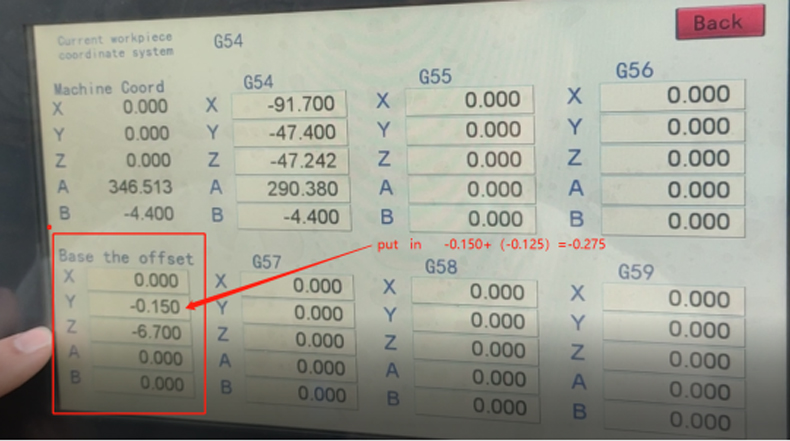

The compensation input value can be input as follows: the initial value of equipment plus the calculated positive or negative base deviation value.

② Examples are as follows

For example, the processing results are as follows

At this moment, the initial value of equipment is

② according to the calculation, when c is less than d, we need to

compensate in the negative direction of compensation box y, and the formula is (C-D)/2= negative number. (0.4-0.9)/2=-0.125 -0.15+(-0.125)=-0.275

Enter -0.275 below

② after compensation, the above processing can be recycled 3-5 times until C = D. 。

Tel/WhatsApp/WeChat:+86 13631516122

Fax:0086-755-28707496 ; 0086-755-28706496 ; 0086-755-84826341

Email:angelbao@camdent.cn

Office address:Room 401, Building B, No.7 Yumiao Road, Buji Sub-district,Long-gang District,Shenzhen 518112, People Republic of China.